One step into a tour of the Kennedy Rice Mill in Mer Rouge called into question one cardinal rule of Cajun cooking for ladies of all ages during a Louisiana Women in Agriculture event.

“My grandma always said you needed to wash the dirt off the rice first, but I’m starting to reconsider,” one participant mused.

Dozens more tried and true southern home chefs agreed. Every aspect of processing, storage and packaging in the mill met meticulous maintenance standards and mom-approved cleanliness conditions.

Kennedy Rice Mill and 4Sisters Rice brand CEO Meryl Kennedy said the efficiency, cleanliness and sustainability of rice processing is a highlight of the industry not often talked about.

“We use pretty much 100% and sell 100% of what we take in. Even the dust is collected and we sell that as well,” Kennedy said. “We've been talking even further about, how can we potentially burn hulls ourselves or do something with the biomass to actually create our own energy even? We’re really focused on making it a full circle supply chain.”

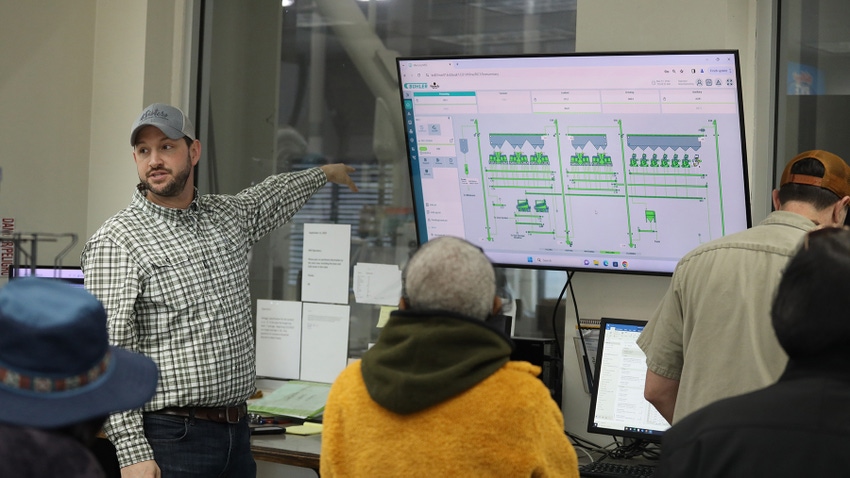

Processing facility

The Kennedy Mill is a regional facility responsible for processing most of the rice grown in northern Louisiana and even into southern Arkansas. Over 50,000 acres of rice feed into Kennedy rice dryer locations and then into the mill in order to meet the daily production demands, where 24-hour production processes and ships 1 million pounds of rice per day.

The family-owned facility has operated since 2012, specializing in filling variety and quality-specific contracts for national brands as well as processing and packaging Kennedy’s family brand, 4Sisters.

“We can track rice all the way back to the individual load,” said plant manager Matt Fowler. “When we trace it back to that tank, we can see what truck it was carried in on, where it was stored, and it traces back to the farm. To track it all the way back can take a lot of work, but we own the entire supply chain, so it makes it a lot easier to work with.”

About the Author(s)

You May Also Like